Electrode Preparation

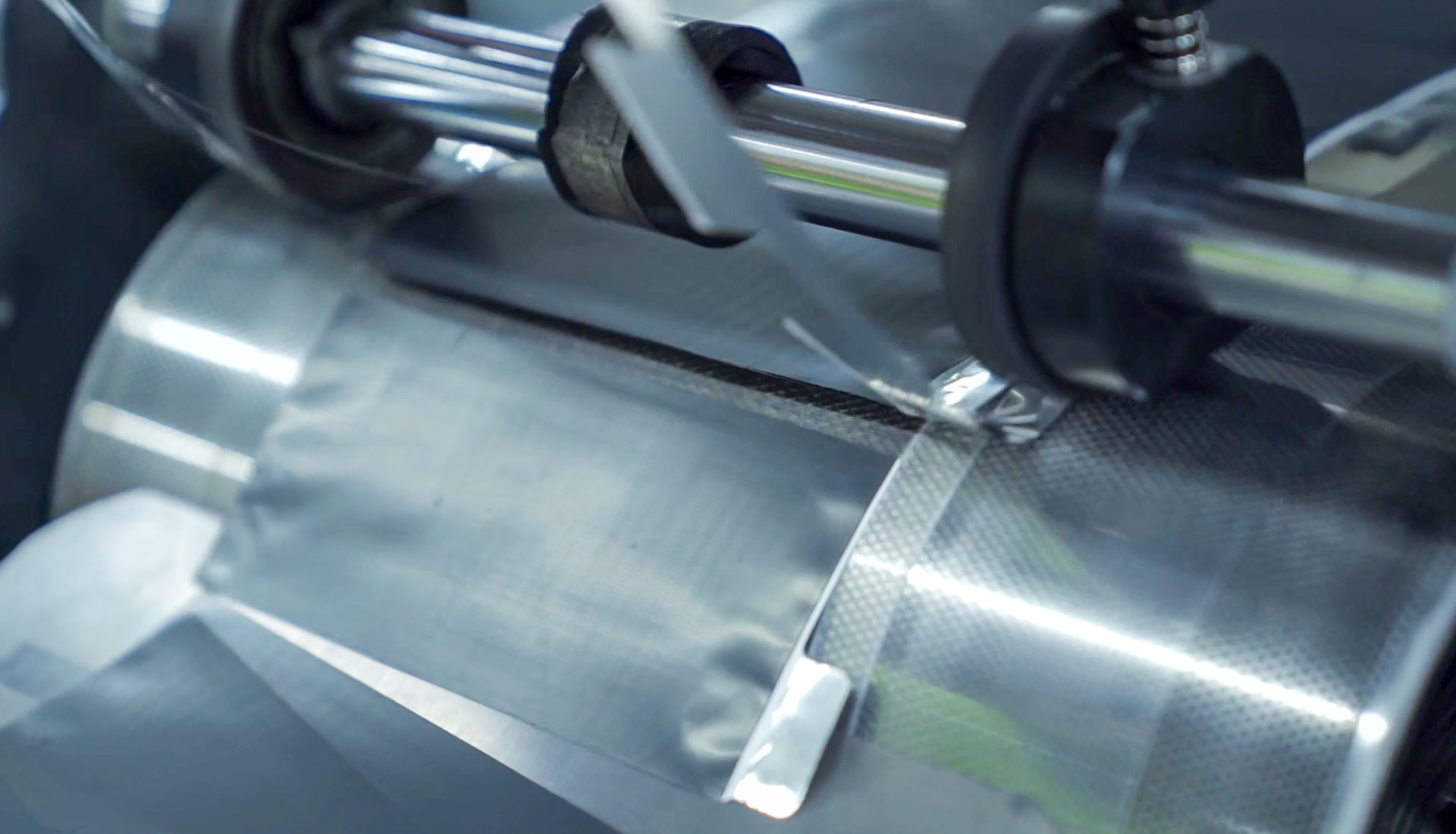

Slurry Preparation/Mixing: Mixing active materials and other ingredients to create the electrode slurry. Coating and Calendering: Coating the slurry onto current collectors and calendering to ensure uniform thickness.

Slurry Preparation/Mixing: Mixing active materials and other ingredients to create the electrode slurry. Coating and Calendering: Coating the slurry onto current collectors and calendering to ensure uniform thickness.

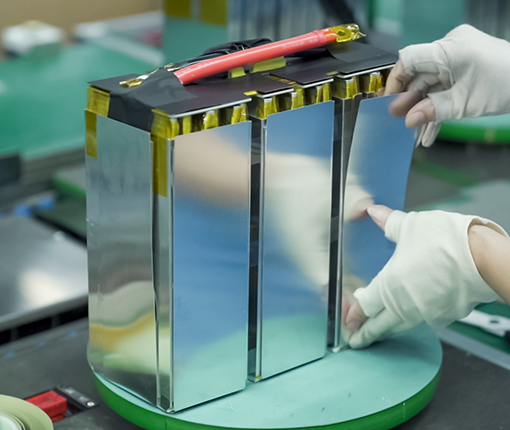

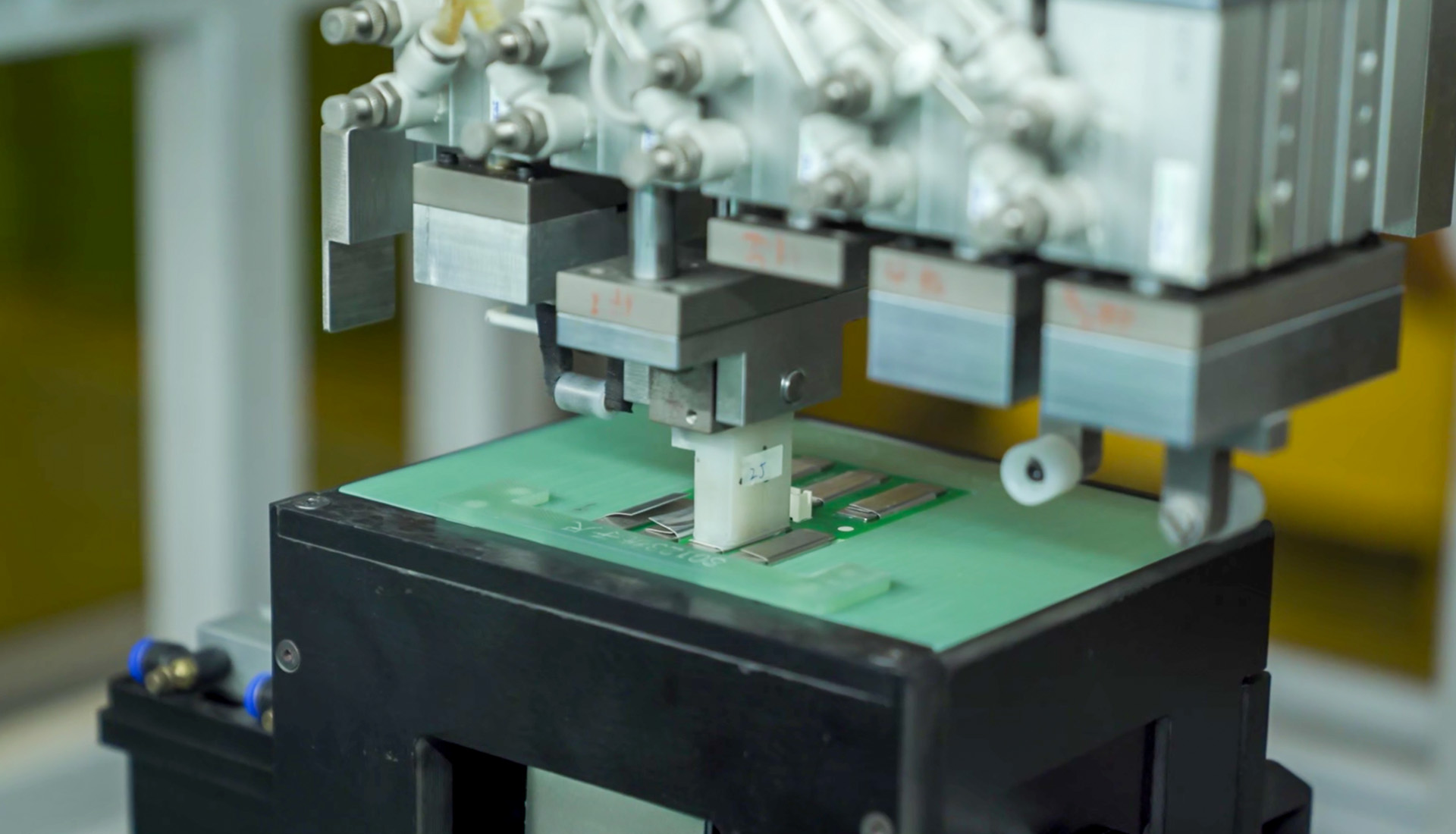

Electrode Cutting: Cutting coated electrode materials into required shapes. Stacking: Stacking positive and negative electrode sheets to form the battery cell structure. Automatic Welding: Precision welding of electrodes to ensure stable electrical connections.

Encapsulation: Initial encapsulation of the assembled cell to ensure sealing. Baking: Drying the cell to remove internal moisture for a stable internal environment. Electrolyte Filling: Injecting electrolyte to enable electrochemical reactions within the cell.

Formation: Conducting the first charge and discharge cycle to activate the battery's chemical reactions. Capacity Testing: Testing battery capacity to ensure it meets design specifications. Cell Puncture and Electrode Tensile Tests: Conducting puncture and tensile tests to confirm safety and reliability.

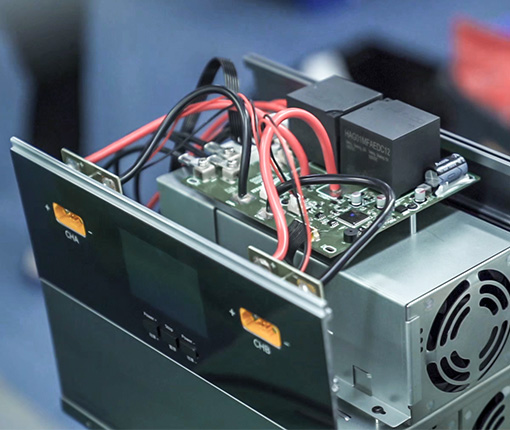

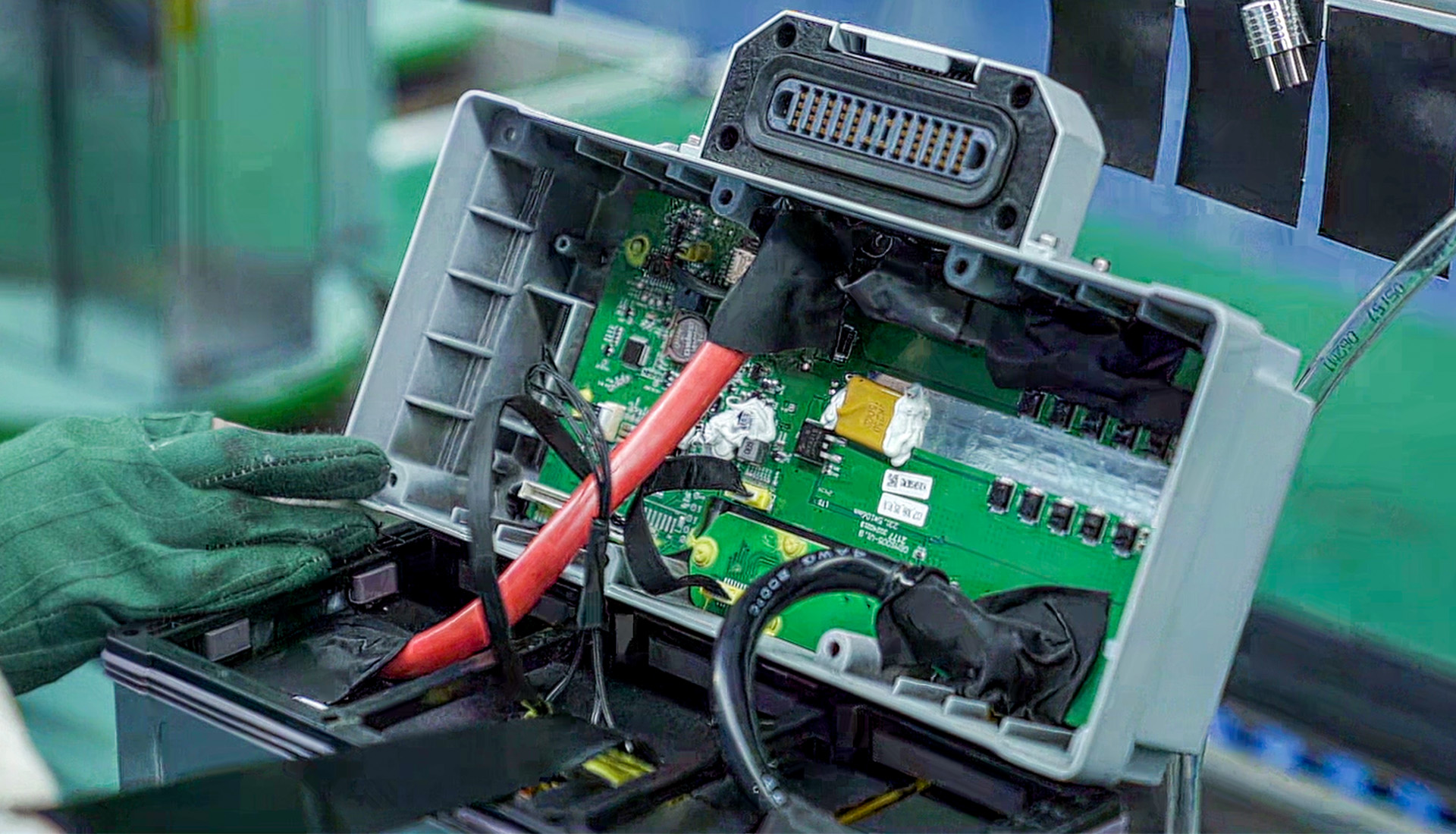

SMT Loading: Mounting electronic components onto the battery’s circuit board. Solder Paste Printing and SPI Inspection: Printing solder paste on the circuit board and inspecting paste distribution through SPI. SMD Placement and AOI Testing: Placing surface-mounted components and conducting AOI tests for solder quality. BMS Programming and Testing: Programming and testing the Battery Management System (BMS) to ensure performance and safety.

Finished Product Testing: Conducting functionality and performance testing on the finished product to meet design and quality standards. OQC (Outgoing Quality Control) Inspection: Performing final inspections to ensure the product meets shipping standards. Software Functionality Testing: Testing product software to verify that all functions work as intende

You can choose one of our nice man